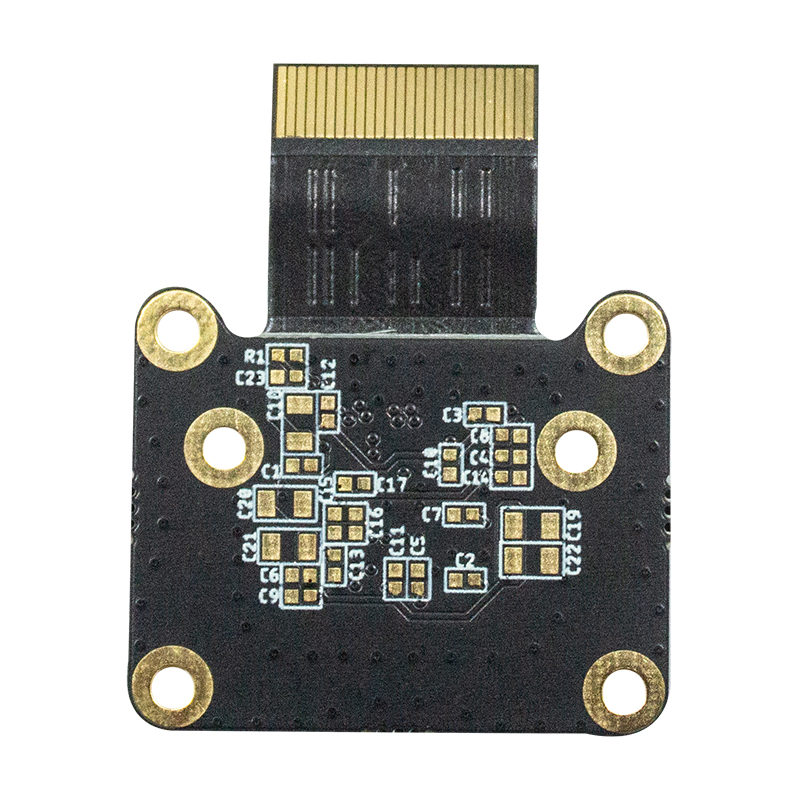

PCB. Gahunda yo kubyara PCB ikubiyemo intambwe zingenzi zingenzi, imwe murimwe ishyira umuringa kuri substrate. Iyi ngingo tuzareba uburyo bwo gushyira umuringa kuri substrate ya PCB mugihe cyo kubyara umusaruro, hanyuma twinjire mubuhanga butandukanye bwakoreshejwe, nka plaque idafite amashanyarazi na electroplating.

1.Ibisahani bidafite amashanyarazi: ibisobanuro, inzira yimiti, ibyiza, ibibi hamwe nibisabwa.

Kugira ngo wumve icyo isahani y'umuringa idafite amashanyarazi, ni ngombwa kumva uko ikora. Bitandukanye na electrodeposition, ishingiye kumashanyarazi yo gushira ibyuma, isahani yumuringa idafite amashanyarazi ni inzira ya autoforeti. Harimo kugabanya imiti igabanya kugabanya umuringa ion kuri substrate, bikavamo umuringa umwe kandi uhuye.

Sukura substrate:Sukura neza hejuru yubutaka kugirango ukureho umwanda wose cyangwa okiside ishobora gukumira. Igikorwa: Igisubizo cyo gukora kirimo catalizari y'agaciro nka palladium cyangwa platine ikoreshwa mugutangiza inzira ya electroplating. Igisubizo cyoroshya gushira umuringa kuri substrate.

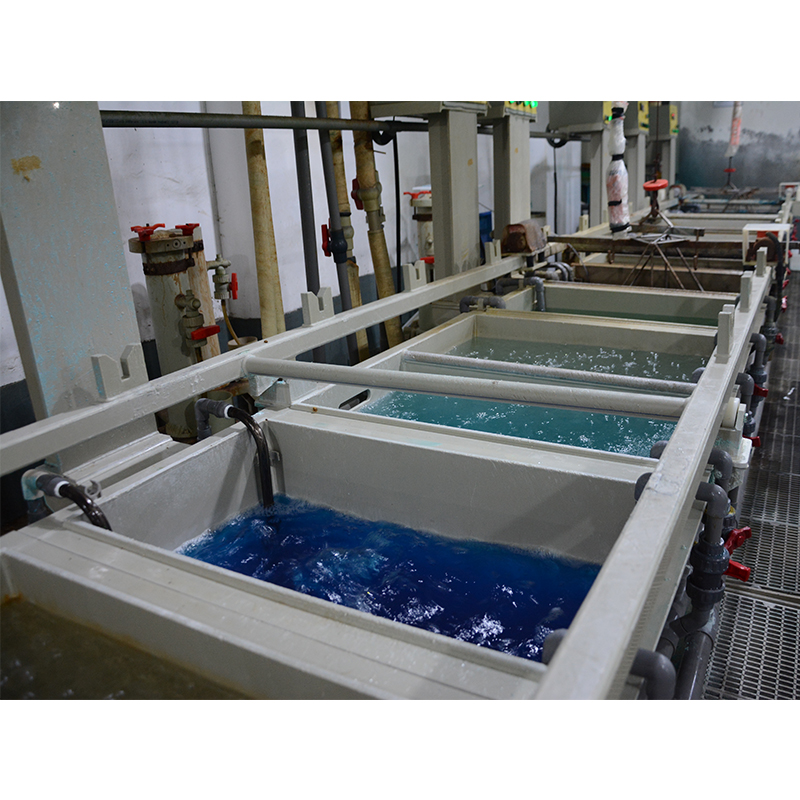

Wibike mu gisubizo:Shira substrate ikora mumashanyarazi adafite amashanyarazi. Igisubizo cyo kubumba kirimo ion z'umuringa, kugabanya ibikoresho ninyongeramusaruro zitandukanye zigenzura uburyo bwo kubika.

Amashanyarazi:Kugabanya ibikoresho mubisubizo bya electroplating chimique bigabanya ion z'umuringa muri atome z'umuringa. Izi atome noneho zihuza hejuru yimikorere, zikora urwego rukomeza kandi rumwe rwumuringa.

Koza kandi wumishe:Umubyimba wumuringa wifuzwa umaze kugerwaho, substrate ikurwa mumasahani hanyuma ikakaraba neza kugirango ikureho imiti isigaye. Kuma substrate isize mbere yo gutunganya. Uburyo bwo gutunganya umuringa wa chimique Uburyo bwa chimique yo gutunganya umuringa utagira amashanyarazi burimo reaction ya redox hagati ya ion z'umuringa no kugabanya ibintu. Intambwe zingenzi mubikorwa zirimo: Gukora: Gukoresha ibyuma byiza bya catalizator nka palladium cyangwa platine kugirango ukore hejuru yubutaka. Catalizator itanga ibibanza nkenerwa byo guhuza imiti ya ion y'umuringa.

Kugabanya umukozi:Kugabanya ibikoresho mubisubizo bya plaque (mubisanzwe formaldehyde cyangwa sodium hypophosphite) itangiza kugabanuka. Izi reagent zitanga electron kuri ion z'umuringa, zikayihindura muri atome z'umuringa.

Autocatalytic reaction:Atome z'umuringa zakozwe no kugabanya reaction zifata hamwe na catalizator hejuru yubutaka kugirango ikore umuringa umwe. Igisubizo kigenda kidakenewe amashanyarazi akoreshwa hanze, bigatuma "isahani idafite amashanyarazi."

Kugenzura igipimo cyo kubitsa:Ibigize hamwe nubushuhe bwibisubizo byisahani, kimwe nibipimo byubushyuhe nkubushyuhe na pH, bigenzurwa neza kugirango igipimo cyo kubitsa kigenzurwe kandi kimwe.

Ibyiza byumuringa udafite amashanyarazi Umuringa:Isahani y'umuringa idafite amashanyarazi ifite uburinganire buhebuje, itanga uburebure bumwe muburyo bugoye kandi ahantu hasuzumwe. Gufata neza: Iyi nzira itanga igifuniko gihuza neza na geometrike idasanzwe nka PCBs. Gufata neza: Isahani y'umuringa idafite amashanyarazi ifatanye cyane nibikoresho bitandukanye byubutaka, harimo plastiki, ububumbyi n’ibyuma. Isahani yatoranijwe: Isahani yumuringa idafite amashanyarazi irashobora guhitamo gushira umuringa mubice byihariye bya substrate ukoresheje tekinike yo guhisha. Igiciro gito: Ugereranije nubundi buryo, isahani yumuringa idafite amashanyarazi nuburyo buhendutse bwo gushira umuringa kuri substrate.

Ingaruka z'umuringa utagira amashanyarazi udafite amashanyarazi Igipimo cyo gutinda buhoro:Ugereranije nuburyo bwa electroplating uburyo, isahani yumuringa idafite amashanyarazi mubisanzwe ifite umuvuduko wo gutinda buhoro, ishobora kwongerera igihe cyose amashanyarazi. Umubyimba muto: Isahani y'umuringa idafite amashanyarazi ikwiranye no kubitsa umuringa unanutse bityo rero ntibikenewe kubisabwa bisaba kubikwa cyane. Ingorabahizi: Inzira isaba kugenzura neza ibipimo bitandukanye, harimo ubushyuhe, pH hamwe nubushakashatsi bwimiti, bigatuma bigorana kubishyira mubikorwa kuruta ubundi buryo bwo gukoresha amashanyarazi. Gucunga imyanda: Kujugunya imyanda isize imyanda irimo ibyuma biremereye bifite uburozi bishobora guteza ibibazo by’ibidukikije kandi bisaba kubyitondera neza.

Ahantu hakoreshwa amashanyarazi adafite amashanyarazi PCB Gukora:Isahani y'umuringa idafite amashanyarazi ikoreshwa cyane mugukora imbaho zicapye zicapye (PCBs) kugirango zikore inzira ziyobora kandi zishyizwe mu mwobo. Inganda ziciriritse: Zigira uruhare runini mugukora ibikoresho bya semiconductor nkibikoresho bya chip hamwe na frame yo kuyobora. Inganda zitwara ibinyabiziga n’ikirere: Isahani y'umuringa idafite amashanyarazi ikoreshwa muguhuza amashanyarazi, guhinduranya hamwe nibikoresho bya elegitoroniki bikora cyane. Imyenda ishushanya kandi ikora: Isahani y'umuringa idafite amashanyarazi irashobora gukoreshwa mugukora imitako ishushanya kumasoko atandukanye, ndetse no kurinda ruswa no kunoza amashanyarazi.

2.Ibisahani bya plaque kuri substrate ya PCB

Isahani y'umuringa kuri substrate ya PCB nintambwe ikomeye mubikorwa byacapwe byumuzunguruko (PCB). Umuringa ukunze gukoreshwa nkibikoresho byamashanyarazi kubera amashanyarazi meza cyane hamwe no gufatana neza na substrate. Gutunganya umuringa bikubiyemo gushyira umuringa muto cyane hejuru yumuringa hejuru ya PCB kugirango habeho inzira ziyobora ibimenyetso byamashanyarazi.

Igikorwa cyo gutunganya umuringa kuri substrate ya PCB mubisanzwe gikubiyemo intambwe zikurikira: Gutegura Ubuso:

Sukura neza substrate ya PCB kugirango ukureho umwanda wose, oxyde cyangwa umwanda ushobora kubangamira gufatira hamwe no kugira ingaruka kumasahani.

Gutegura amashanyarazi:

Tegura igisubizo cya electrolyte irimo sulfate y'umuringa nkisoko ya ion y'umuringa. Electrolyte irimo kandi inyongeramusaruro igenzura uburyo bwo gufata amasahani, nkibikoresho byo kuringaniza, ibimurika, hamwe na pH.

Amashanyarazi:

Shira ibice bya PCB byateguwe mubisubizo bya electrolyte hanyuma ushyireho amashanyarazi ataziguye. PCB ikora nka cathode ihuza, mugihe anode y'umuringa nayo ihari mugisubizo. Ibiriho bitera ion z'umuringa muri electrolyte kugabanuka no gushyirwa hejuru ya PCB.

Kugenzura ibipimo byerekana:

Ibipimo bitandukanye bigenzurwa neza mugihe cyo gufata amasahani, harimo ubucucike buriho, ubushyuhe, pH, gukurura no gufata umwanya. Ibipimo bifasha kwemeza gushira, gufatana, hamwe nubunini bwifuzwa bwumuringa.

Kuvura nyuma yo gufata:

Umubyimba wumuringa wifuzwa umaze kugerwaho, PCB ikurwa mubwogero bwa plaque hanyuma ikakaraba kugirango ikureho igisubizo gisigaye cya electrolyte. Ubundi buryo bwo kuvura nyuma yisahani, nko gusukura hejuru hamwe na passivation, birashobora gukorwa kugirango ubuziranenge nuburinganire bwumuringa bikozwe mu muringa.

Ibintu bigira ingaruka nziza kumashanyarazi:

Gutegura Ubuso:

Gusukura neza no gutegura ubuso bwa PCB nibyingenzi kugirango ukureho ibintu byose byanduza cyangwa ibice bya oxyde kandi byemeze neza ko umuringa usa neza. Gutegura igisubizo:

Ibigize igisubizo cya electrolyte, harimo nubunini bwa sulfate yumuringa ninyongeramusaruro, bizagira ingaruka kumiterere yisahani. Isahani yo kwiyuhagiriramo igomba kugenzurwa neza kugirango igere kubiranga isahani.

Ibipimo byerekana:

Kugenzura ibipimo byerekana nkubucucike bwubu, ubushyuhe, pH, gukurura no gufata umwanya birakenewe kugirango habeho gushira hamwe, gufatana nubunini bwumuringa.

Ibikoresho byerekana:

Ubwoko nubwiza bwibikoresho bya PCB bizagira ingaruka kumyifatire hamwe nubwiza bwumuringa. Ibikoresho bitandukanye bya substrate birashobora gusaba guhindurwa muburyo bwo gukora ibisubizo byiza.

Ubuso bukabije:

Ubuso bwubuso bwa substrate ya PCB bizagira ingaruka kumyifatire hamwe nubuziranenge bwumuringa. Gutegura neza neza no kugenzura ibipimo bifata bifasha kugabanya ibibazo bijyanye nuburakari

Ibyiza bya PCB substrate y'umuringa:

Amashanyarazi meza cyane:

Umuringa uzwiho kuba ufite amashanyarazi menshi, bigatuma uhitamo neza ibikoresho bya PCB. Ibi bituma imiyoboro ikora neza kandi yizewe. Kwizirika neza:

Umuringa werekana neza cyane kubutaka butandukanye, byemeza isano ikomeye kandi irambye hagati yigitereko na substrate.

Kurwanya ruswa:

Umuringa ufite imbaraga zo kurwanya ruswa, urinda ibice bigize PCB no kwemeza igihe kirekire. Solderability: Isahani yumuringa itanga ubuso bubereye kugurisha, byoroshye guhuza ibikoresho bya elegitoronike mugihe cyo guterana.

Kongera ubushyuhe bwo gukwirakwiza:

Umuringa nuyobora neza ubushyuhe, butuma ubushyuhe bukwirakwizwa bwa PCBs. Ibi ni ngombwa cyane cyane kubikorwa byingufu zikoreshwa.

Imipaka n'imbogamizi z'umuriro w'amashanyarazi:

Kugenzura umubyimba:

Kugera kugenzura neza kubyimbye byumuringa birashobora kugorana, cyane cyane mubice bigoye cyangwa ahantu hafunganye kuri PCB. Guhuriza hamwe: Kugenzura umuringa umwe hejuru yubuso bwa PCB, harimo ahantu hasubiwemo nibintu byiza, birashobora kugorana.

Igiciro:

Gukoresha umuringa w'amashanyarazi birashobora kuba bihenze ugereranije n'ubundi buryo bwo gukoresha amashanyarazi bitewe n'igiciro cyo gufata imiti ya tanki, ibikoresho, no kuyitaho.

Gucunga imyanda:

Kurandura ibisubizo byakoreshejwe mu gutunganya no gutunganya amazi y’amazi arimo ion z'umuringa n’indi miti bisaba uburyo bukwiye bwo gucunga imyanda kugirango bigabanye ingaruka z’ibidukikije.

Ibikorwa bigoye:

Gukoresha umuringa birimo ibipimo byinshi bisaba kugenzura neza, bisaba ubumenyi bwihariye hamwe no gushiraho amasahani.

3.Gereranya hagati yumuringa utagira amashanyarazi na electroplating

Imikorere n'itandukaniro ryiza:

Hariho itandukaniro ryinshi mubikorwa nubuziranenge hagati yumuringa udafite amashanyarazi hamwe na electroplating mubice bikurikira:

Amashanyarazi adafite amashanyarazi ni uburyo bwo kubika imiti idasaba inkomoko y’amashanyarazi, mu gihe amashanyarazi arimo gukoresha amashanyarazi ataziguye kugira ngo abike igice cy'umuringa. Iri tandukaniro muburyo bwo kubitsa rishobora kuganisha ku gutandukana muburyo bwiza.

Amashanyarazi adafite amashanyarazi muri rusange atanga icyerekezo kimwe hejuru yubutaka bwose, harimo ahantu hasubiwemo nibintu byiza. Ibi ni ukubera ko isahani ibaho ku buso bwose utitaye ku cyerekezo cyabo. Ku rundi ruhande, amashanyarazi arashobora kugira ikibazo cyo kugera kumurongo umwe mubice bigoye cyangwa bigoye kugera.

Amashanyarazi y'umuringa adafite amashanyarazi arashobora kugera ku kigereranyo cyo hejuru (igipimo cy'uburebure buranga n'ubugari) kuruta amashanyarazi. Ibi bituma bikwiranye na porogaramu zisaba ibintu byinshi byagereranijwe, nkibinyuze muri PCBs.

Isahani y'umuringa idafite amashanyarazi muri rusange itanga ubuso bworoshye, buringaniye kuruta amashanyarazi.

Amashanyarazi arashobora rimwe na rimwe kuvamo kubitsa kutaringaniye, gukabije cyangwa kubusa bitewe nimpinduka zubucucike bwubu hamwe nuburyo bwo kwiyuhagira. Ubwiza bwumubano uri hagati yumuringa wumuringa hamwe na substrate birashobora gutandukana hagati yumuringa udafite amashanyarazi na electroplating.

Amashanyarazi adafite amashanyarazi muri rusange atanga uburyo bwiza bwo guhuza imiti bitewe nuburyo bwo guhuza imiti yumuringa utagira amashanyarazi kuri substrate. Isahani yishingikiriza kumashanyarazi na mashanyarazi, bishobora kuvamo intege nke mubihe bimwe.

Kugereranya ibiciro:

Gutanga imiti na Electroplating: Mugihe ugereranije ibiciro byo gusya umuringa udafite amashanyarazi hamwe na electroplating, ibintu byinshi bigomba kwitabwaho:

Ibiciro bya shimi:

Amashanyarazi adafite amashanyarazi muri rusange asaba imiti ihenze ugereranije na electroplating. Imiti ikoreshwa mu isahani idafite amashanyarazi, nko kugabanya imiti na stabilisateur, muri rusange ni umwihariko kandi uhenze.

Ibiciro by'ibikoresho:

Ibikoresho byo gushiraho bisaba ibikoresho bigoye kandi bihenze, harimo ibikoresho byamashanyarazi, bikosora na anode. Sisitemu yo gushiraho umuringa idafite amashanyarazi iroroshye kandi isaba ibice bike.

Amafaranga yo gufata neza:

Ibikoresho byo gushiraho birashobora gusaba kubungabunga buri gihe, kalibrasi, no gusimbuza anode cyangwa ibindi bice. Sisitemu yo gushiraho umuringa idafite amashanyarazi muri rusange isaba kubungabungwa kenshi kandi bifite amafaranga make yo kubungabunga.

Ikoreshwa rya Shitingi ya Shitingi:

Sisitemu yo gushiraho ikoresha imiti ya plaque ku kigero cyo hejuru kubera gukoresha amashanyarazi. Imiti ikoreshwa na sisitemu yo gutunganya umuringa idafite amashanyarazi ni mike kuko reaction ya electroplating ibaho binyuze mumiti.

Amafaranga yo gucunga imyanda:

Amashanyarazi atanga imyanda yinyongera, harimo gukoresha ubwogero bwogukoresha no kwoza amazi yanduye ioni yicyuma, bisaba kuvurwa no kujugunywa. Ibi byongera igiciro rusange cyo gufata amasahani. Amashanyarazi adafite amashanyarazi atanga imyanda mike kuko idashingira kumasoko ahoraho yo gutanga ibyuma mubyogero.

Ingorane nimbogamizi zo gukwirakwiza amashanyarazi no kubitsa imiti:

Gukoresha amashanyarazi bisaba kugenzura neza ibipimo bitandukanye nkubucucike buriho, ubushyuhe, pH, igihe cyo guterana no gukurura. Kugera kububiko bumwe hamwe nibyifuzo byo gushiraho birashobora kuba ingorabahizi, cyane cyane muri geometrike igoye cyangwa ahantu hake. Gukwirakwiza isahani yo kwiyuhagira hamwe nibipimo bishobora gusaba ubushakashatsi nubuhanga.

Isahani y'umuringa idafite amashanyarazi nayo isaba kugenzura ibipimo nko kugabanya ubukana bwa agent, ubushyuhe, pH nigihe cyo gufata. Nyamara, kugenzura ibyo bipimo muri rusange ntabwo ari ingenzi cyane mu isahani idafite amashanyarazi kuruta muri electroplating. Kugera kubintu byifuzwa byapimwe, nkigipimo cyo kubitsa, ubunini, hamwe no gufatira hamwe, birashobora gusaba ko hajyaho uburyo bwo kugenzura no kugenzura inzira.

Mumashanyarazi ya electroplating na electroless, guhuza ibikoresho bitandukanye byubutaka birashobora kuba ikibazo rusange. Mbere yo kuvura hejuru yubutaka kugirango ukureho umwanda kandi uteze imbere gukomera ni ngombwa kubikorwa byombi.

Gukemura ibibazo no gukemura ibibazo muri electroplating cyangwa amashanyarazi adafite amashanyarazi bisaba ubumenyi n'uburambe. Ibibazo nkuburakari, kubitsa kutaringaniye, ubusa, kubyimba, cyangwa gufatana nabi bishobora kugaragara mugihe cyombi, kandi kumenya intandaro no gufata ingamba zo gukosora birashobora kugorana.

Ingano yo gukoresha buri tekinoroji:

Amashanyarazi akoreshwa cyane mubikorwa bitandukanye birimo ibikoresho bya elegitoroniki, ibinyabiziga, icyogajuru hamwe n imitako bisaba kugenzura neza umubyimba, kurangiza neza kandi byifuzwa bifatika. Ikoreshwa cyane muburyo bwo gushushanya, gutwikira ibyuma, kurinda ruswa no gukora ibikoresho bya elegitoroniki.

Isahani y'umuringa idafite amashanyarazi ikoreshwa cyane cyane mu nganda za elegitoroniki, cyane cyane mu gukora imbaho zicapye (PCBs). Byakoreshejwe mugukora inzira ziyobora, kugurishwa hejuru nubuso burangirira kuri PCBs. Isahani y'umuringa idafite amashanyarazi nayo ikoreshwa muguhuza ibyuma bya plastiki, kubyara imiringa ihuza imifuka ya semiconductor, nibindi bikorwa bisaba gushira umuringa umwe kandi uhuye.

4.Ibikoresho byo kubika ibicuruzwa kubwoko butandukanye bwa PCB

Uruhande rumwe PCB:

Muri PCBs imwe, kubika umuringa mubisanzwe bikorwa hakoreshejwe uburyo bwo gukuramo. Ubusanzwe insimburangingo ikozwe mubintu bidatwara ibintu nka FR-4 cyangwa fenolike, bisizwe hamwe n'umuringa muto cyane wumuringa kuruhande rumwe. Igice cy'umuringa gikora nk'inzira iyobora umuzenguruko. Inzira itangirana no gusukura no gutegura hejuru yubutaka kugirango harebwe neza. Ibikurikira nugukoresha urwego ruto rwibikoresho bifotora, bigaragazwa numucyo UV ukoresheje fotomask kugirango usobanure imiterere yumuzunguruko. Ahantu hagaragaye kurwanywa hacika intege hanyuma bagahanagurwa, bikerekana umuringa uri munsi. Ahantu h'umuringa hagaragaye noneho hashyirwaho hakoreshejwe etchant nka chloride ferric cyangwa ammonium persulfate. Etchant ihitamo gukuramo umuringa wagaragaye, hasigara icyitegererezo cyumuzingi. Ibisigaye birwanya noneho biramburwa, hasigara ibimenyetso byumuringa. Nyuma yuburyo bwo gutobora, PCB irashobora kunyuramo izindi ntambwe zo gutegura ubuso nka masike yagurishijwe, icapiro rya ecran, hamwe nogukoresha ibice birinda kugirango birambe kandi birinde ibidukikije.

Impande ebyiri PCB:

Impande ebyiri PCB ifite umuringa kumpande zombi za substrate. Inzira yo kubitsa umuringa kumpande zombi ikubiyemo intambwe yinyongera ugereranije na PCB imwe. Inzira isa na PCB uruhande rumwe, itangirana no gukora isuku no gutegura ubuso bwubutaka. Igice cyumuringa gishyirwa kumpande zombi za substrate ukoresheje umuringa utagira amashanyarazi cyangwa amashanyarazi. Electroplating isanzwe ikoreshwa kuriyi ntambwe kuko ituma igenzura neza kubyimbye nubwiza bwumuringa. Iyo umuringa umaze kubikwa, impande zombi zishushanyijeho fotoreziste kandi uburyo bwumuzunguruko busobanurwa binyuze mumagambo nintambwe yiterambere bisa nibya PCB imwe. Ahantu h'umuringa hagaragaye noneho hashyizweho kugirango habeho inzira zumuzingi zisabwa. Nyuma yo gutobora, résistance ikurwaho hanyuma PCB ikanyura mu zindi ntambwe nko gutunganya mask yo kugurisha no kuvura hejuru kugirango irangize guhimba PCB impande zombi.

PCB:

PCBs nyinshi igizwe nibice byinshi byumuringa hamwe nibikoresho byiziritse hejuru yundi. Kubika umuringa muri PCB nyinshi zirimo intambwe nyinshi zo gukora inzira ziyobora hagati yinzego. Inzira itangirana no guhimba PCB kugiti cye, bisa na PCBs imwe cyangwa impande ebyiri. Buri cyiciro cyateguwe kandi fotora ikoreshwa mugusobanura imiterere yumuzunguruko, hagakurikiraho gushira umuringa ukoresheje amashanyarazi cyangwa amashanyarazi adafite amashanyarazi. Nyuma yo kubitsa, buri cyiciro gitwikiriwe nibikoresho byiziritse (mubisanzwe epoxy-ishingiye kuri prereg cyangwa resin) hanyuma bigashyirwa hamwe. Ibice byahujwe hakoreshejwe gucukura neza nuburyo bwo kwiyandikisha kugirango habeho guhuza neza hagati yinzego. Iyo ibice bimaze guhuzwa, vias ikorwa no gucukura umwobo unyuze mubice byihariye aho bisabwa guhuza. Viyasi noneho yashizwemo umuringa ukoresheje amashanyarazi cyangwa amashanyarazi adafite amashanyarazi kugirango habeho guhuza amashanyarazi hagati yabyo. Inzira irakomeza mugusubiramo intambwe, gutobora, no guteramo umuringa kugeza igihe ibyangombwa byose bisabwa hamwe n’imikoranire. Intambwe yanyuma ikubiyemo kuvura hejuru, kugurisha mask ya progaramu nibindi bikorwa byo kurangiza kugirango urangize gukora PCB nyinshi.

Umuyoboro mwinshi (HDI) PCB:

HDI PCB ni PCB igizwe ninzego nyinshi zagenewe kwakira uruziga rwinshi kandi rufite ibintu bito. Gushyira umuringa muri HDI PCBs birimo tekinoroji igezweho kugirango ishoboze ibintu byiza nibishushanyo mbonera. Inzira itangirana no gukora ultra-thin layers nyinshi, akenshi bita ibikoresho byingenzi. Izi ngirangingo zifite ifu yumuringa yoroheje kuruhande kandi ikozwe mubikoresho bikora cyane nka BT (Bismaleimide Triazine) cyangwa PTFE (Polytetrafluoroethylene). Ibikoresho byibanze byegeranye kandi bigashyirwa hamwe kugirango habeho imiterere myinshi. Gucukura lazeri noneho bikoreshwa mugukora microvias, ni utwobo duto duhuza ibice. Microvias mubisanzwe yuzuyemo ibikoresho byayobora nkumuringa cyangwa epoxy ikora. Nyuma ya microvias zimaze gushingwa, izindi nzego zashyizwe hamwe kandi zomekwa. Gukurikirana lamination hamwe na lazeri yo gusubiramo birasubirwamo kugirango habeho ibice byinshi byegeranye hamwe na microvia ihuza. Hanyuma, umuringa ushyirwa hejuru ya HDI PCB ukoresheje tekinoroji nka electroplating cyangwa amashanyarazi adafite amashanyarazi. Urebye ibintu byiza hamwe nubucucike bukabije bwa HDI PCBs, kubitsa bigenzurwa neza kugirango ugere ku mubyimba ukenewe wumuringa nubuziranenge. Inzira irangirana nubundi buryo bwo kuvura no kurangiza kugirango urangize inganda za HDI PCB, zishobora kuba zirimo kugurisha masike yo kugurisha, kurangiza kurangiza no kugerageza.

Ikibaho cyumuzunguruko cyoroshye:

PCB ihindagurika, izwi kandi nka flex circuits, yashizweho kugirango ihindurwe kandi ibashe guhuza imiterere itandukanye cyangwa yunamye mugihe ikora. Kubika umuringa muri PCB byoroshye birimo tekinike yihariye yujuje ibyangombwa bisabwa. PCB ihindagurika irashobora kuba uruhande rumwe, uruhande rumwe, cyangwa urwego rwinshi, kandi tekinike yo kubika umuringa iratandukanye bitewe nibisabwa. Muri rusange, PCBs yoroheje ikoresha foil yoroheje y'umuringa ugereranije na PCB zikomeye kugirango ugere ku guhinduka. Kuburyo bumwe bworoshye PCBs, inzira isa na PCBs imwe rukumbi, ni ukuvuga, umuringa muto wumuringa ushyirwa kumurongo woroshye ukoresheje amashanyarazi adafite amashanyarazi, amashanyarazi, cyangwa guhuza byombi. Kubice bibiri cyangwa byinshi-byoroshye PCBs, inzira ikubiyemo gushyira umuringa kumpande zombi za substrate yoroheje ukoresheje umuringa udafite amashanyarazi cyangwa amashanyarazi. Urebye imiterere yihariye yubukanishi bwibikoresho byoroshye, kubitsa bigenzurwa neza kugirango byemeze neza kandi byoroshye. Nyuma yo gushira umuringa, PCB ihindagurika inyura mubikorwa byinyongera nko gucukura, gushushanya imirongo, hamwe nintambwe yo kuvura hejuru kugirango habeho umuzenguruko ukenewe kandi urangize gukora PCB yoroheje.

5.Iterambere n'udushya mu Kubika Umuringa kuri PCBs

Iterambere ry'ikoranabuhanga rigezweho: Mu myaka yashize, tekinoroji yo kubika umuringa kuri PCBs yakomeje guhinduka no gutera imbere, bigatuma imikorere yiyongera kandi yizewe. Bimwe mubikorwa bigezweho byikoranabuhanga mububiko bwa PCB burimo:

Ikoranabuhanga rigezweho:

Ikoranabuhanga rishya ryo gusya, nka plase plaque na reverse pulse plate, ryateguwe kugirango rigere kumuringa mwiza kandi umwe. Izi tekinoroji zifasha gutsinda ibibazo nkubuso bwubuso, ingano nubunini bwikwirakwizwa kugirango tunoze imikorere yamashanyarazi.

Metallisation itaziguye:

Ubukorikori gakondo bwa PCB burimo intambwe nyinshi zo gukora inzira ziyobora, harimo no kubitsa imbuto mbere yo gusya umuringa. Iterambere ryibikorwa bitaziguye bikuraho ibikenerwa byimbuto zitandukanye, bityo koroshya inzira yinganda, kugabanya ibiciro no kuzamura ubwizerwe.

Ikoranabuhanga rya Microvia:

Microvias ni utwobo duto duhuza ibice bitandukanye muri PCB nyinshi. Iterambere mu ikoranabuhanga rya microvia nko gucukura laser na plasma etching ituma habaho mikorobe ntoya, isobanutse neza, ituma imiyoboro yubucucike bwiyongera kandi ikanonosora ubuziranenge bwibimenyetso. Ubuso bwa Finish Guhanga udushya: Kurangiza ubuso nibyingenzi mukurinda ibimenyetso byumuringa okiside no gutanga solderability. Iterambere mu buhanga bwo kuvura hejuru, nka Immersion Silver (ImAg), Organic Solderability Preservative (OSP), na Electroless Nickel Immersion Gold (ENIG), bitanga uburyo bwiza bwo kurinda ruswa, kunoza ubwishingizi, no kongera ubwizerwe muri rusange.

Nanotehnologiya no Kubika Umuringa: Nanotehnologiya igira uruhare runini mugutezimbere kwa PCB umuringa. Bimwe mubikorwa bya nanotehnologiya mububiko bwumuringa harimo:

Isahani ishingiye kuri Nanoparticle:

Umuringa wa nanoparticles urashobora kwinjizwa mubisubizo kugirango ushyire mubikorwa. Iyi nanoparticles ifasha kunoza umuringa, ingano no kugabura, bityo bikagabanya ubukana no kongera amashanyarazi.

Ibikoresho byayobora Nanostructures:

Ibikoresho bya Nanostructures, nka karubone nanotubes na graphene, birashobora kwinjizwa muri substrate ya PCB cyangwa bigakorwa nkuzuza ibintu mugihe cyo kubitsa. Ibi bikoresho bifite amashanyarazi menshi, imbaraga za mashini hamwe nubushyuhe bwumuriro, bityo bikazamura imikorere rusange ya PCB.

Nanocoating:

Nanocoating irashobora gukoreshwa hejuru ya PCB kugirango irusheho kugenda neza, kugurishwa no kurinda ruswa. Iyi myenda ikozwe muri nanocomposite itanga uburinzi bwiza kubintu bidukikije kandi ikongerera ubuzima PCB.

Nanoscale ihuza:Imiyoboro ya Nanoscale, nka nanowire na nanorods, zirimo gushakishwa kugirango hashobore kubaho imiyoboro myinshi muri PCBs. Izi nzego zorohereza guhuza imirongo myinshi mukarere gato, bigatuma iterambere ryibikoresho bito bya elegitoroniki byoroheje.

Inzitizi nicyerekezo kizaza: Nubwo hari iterambere ryinshi, imbogamizi n amahirwe menshi biracyakomeza kunozwa umuringa kuri PCB. Ibibazo bimwe byingenzi hamwe nicyerekezo kizaza harimo:

Umuringa Uzuza Imiterere Yikigereranyo Cyinshi:

Inzego zingana cyane nka vias cyangwa microvias zitanga imbogamizi mugushikira umuringa umwe kandi wizewe. Ubundi bushakashatsi burakenewe kugirango habeho tekinoroji yo gutera imbere cyangwa ubundi buryo bwo kuzuza kugirango utsinde izo mbogamizi kandi tumenye neza ko umuringa ushyizwe muburyo bugereranije.

Kugabanya ubugari bw'umuringa:

Mugihe ibikoresho bya elegitoronike bigenda biba bito kandi bigahinduka, gukenera umuringa muto wumuringa bikomeje kwiyongera. Ikibazo ni ukugera kumuringa umwe kandi wizewe muri izi nzira zifunganye, kwemeza imikorere yamashanyarazi kandi yizewe.

Ubundi buryo bwo kuyobora ibikoresho:

Mugihe umuringa aribikoresho bikoreshwa cyane mu kuyobora, ibikoresho bindi nka silver, aluminium, na nanotube ya karubone birashakishwa kubera imiterere yihariye nibyiza byo gukora. Ubushakashatsi bw'ejo hazaza bushobora kwibanda ku guteza imbere tekinoroji yo kubitsa kubindi bikoresho byayobora kugirango batsinde ibibazo nko gufatana, kurwanya, no guhuza nibikorwa bya PCB. IbidukikijeInzira Zinshuti:

Inganda za PCB zihora zikora inzira zangiza ibidukikije. Iterambere ry'ejo hazaza rishobora kwibanda ku kugabanya cyangwa gukuraho ikoreshwa ry’imiti yangiza mu gihe cyo guta umuringa, gukoresha neza ingufu, no kugabanya imyanda igabanya ingaruka z’ibidukikije ku nganda za PCB.

Kwigana no Kwiteza imbere:

Uburyo bwo kwigana no kwerekana imiterere bifasha guhindura uburyo bwo kubika umuringa, guhanura imyitwarire y'ibipimo byo kubitsa, no kunoza ukuri no gukora neza mubikorwa bya PCB. Iterambere ry'ejo hazaza rishobora kwinjiza uburyo bwo kwigana no kwerekana ibikoresho mu buryo bwo gushushanya no gukora kugirango bishoboke kugenzura neza no gukora neza.

6.Ubwishingizi Bwiza no Kugenzura Umuringa Kubika PCB Substrates

Akamaro k'ubwishingizi bufite ireme: Ubwishingizi bufite ireme ni ngombwa mu buryo bwo kubika umuringa kubera impamvu zikurikira:

Ibicuruzwa byizewe:

Gushyira umuringa kuri PCB bigize ishingiro ryo guhuza amashanyarazi. Kwemeza ubwiza bwumuringa ni ingenzi kumikorere yizewe kandi iramba yibikoresho bya elegitoroniki. Kubika umuringa muke birashobora gukurura amakosa yo guhuza, ibimenyetso byerekana, hamwe no kugabanuka muri PCB kwizerwa.

Imashanyarazi:

Ubwiza bw'isahani y'umuringa bugira ingaruka ku buryo butaziguye imikorere y'amashanyarazi ya PCB. Umubyimba umwe wumuringa no gukwirakwiza, kurangiza neza neza, no gufatana neza ni ngombwa kugirango ugere ku barwanya buke, kohereza ibimenyetso neza, no gutakaza ibimenyetso bike.

Kugabanya ibiciro:

Ubwishingizi bufite ireme bufasha kumenya no gukumira ibibazo hakiri kare, bikagabanya gukenera gukora cyangwa gukuraho PCB zifite inenge. Ibi birashobora kuzigama ibiciro no kuzamura imikorere muri rusange.

Guhaza abakiriya:

Gutanga ibicuruzwa byujuje ubuziranenge ni ngombwa mu guhaza abakiriya no kubaka izina ryiza mu nganda. Abakiriya biteze ibicuruzwa byizewe kandi biramba, kandi ubwishingizi bufite ireme butuma umuringa wujuje cyangwa urenze ibyo byateganijwe.

Uburyo bwo gupima no kugenzura uburyo bwo kubika umuringa: Uburyo butandukanye bwo gupima no kugenzura bukoreshwa kugirango hamenyekane ubwiza bwumuringa kuri PCBs. Bumwe muburyo busanzwe burimo:

Kugenzura Amashusho:

Igenzura ryibonekeje nuburyo bwibanze kandi bwingenzi bwo kumenya inenge igaragara nkibishushanyo, amenyo cyangwa ububi. Iri genzura rirashobora gukorwa nintoki cyangwa hifashishijwe sisitemu yo kugenzura optique (AOI).

Microscopi:

Microscopi ikoresheje tekinike nka scanning electron microscopie (SEM) irashobora gutanga isesengura rirambuye ryumuringa. Irashobora kugenzura neza kurangiza hejuru, gufatana hamwe nuburinganire bwumuringa.

Isesengura X-ray:

Ubuhanga bwo gusesengura X-ray, nka X-ray fluorescence (XRF) na X-ray itandukanya (XRD), bikoreshwa mugupima ibice, umubyimba nogukwirakwiza ububiko bwumuringa. Ubu buhanga bushobora kumenya umwanda, ibigize ibice, no gutahura ibitagenda neza mu guta umuringa.

Ikizamini cy'amashanyarazi:

Kora uburyo bwo gupima amashanyarazi, harimo gupima kurwanya no kugerageza gukomeza, kugirango usuzume imikorere y'amashanyarazi yabitswe. Ibi bizamini bifasha kwemeza ko urwego rwumuringa rufite ubushobozi bukenewe kandi ko nta gufungura cyangwa ikabutura muri PCB.

Ikizamini cyimbaraga za Peel:

Ikizamini cyimbaraga zipima gipima imbaraga zihuza hagati yumuringa na substrate ya PCB. Igena niba kubitsa umuringa bifite imbaraga zihagije kugirango bihangane nibikorwa bisanzwe nibikorwa bya PCB.

Inganda n’amabwiriza y’inganda: Inganda za PCB zikurikiza amahame n’inganda zitandukanye kugira ngo ireme ry’umuringa. Bimwe mu bipimo ngenderwaho n'amabwiriza arimo:

IPC-4552:

Ibipimo ngenderwaho byerekana ibisabwa kuri elegitoroniki ya nikel / kwibiza zahabu (ENIG) ivura ubusanzwe ikoreshwa kuri PCBs. Irasobanura byibuze uburebure bwa zahabu, ubunini bwa nikel hamwe nubuziranenge bwubutaka bwizewe kandi burambye bwo kuvura ENIG.

IPC-A-600:

Igipimo cya IPC-A-600 gitanga umurongo ngenderwaho wo kwemerera PCB, harimo ibipimo byo gutondekanya umuringa, inenge zo hejuru nibindi bipimo byiza. Ikora nkibisobanuro byo kugenzura no kwemeza ibipimo byo gushira umuringa kuri PCBs. Amabwiriza ya RoHS:

Kubuza ibintu byangiza (RoHS) amabwiriza agenga ikoreshwa ryibintu bimwe na bimwe bishobora guteza akaga ibicuruzwa bya elegitoroniki, birimo gurş, mercure na kadmium. Kubahiriza amabwiriza ya RoHS yemeza ko kubitsa umuringa kuri PCB bitarimo ibintu byangiza, bigatuma bitekana kandi bitangiza ibidukikije.

ISO 9001:

ISO 9001 nigipimo mpuzamahanga kuri sisitemu yo gucunga neza. Gushiraho no gushyira mu bikorwa sisitemu yo gucunga ubuziranenge ishingiye kuri ISO 9001 yemeza ko inzira n’ubugenzuzi bikwiye kugira ngo bihore bitanga ibicuruzwa byujuje ibyifuzo by’abakiriya, harimo n’ubuziranenge bw’umuringa kuri PCBs.

Kugabanya ibibazo bisanzwe hamwe nudusembwa: Bimwe mubibazo bisanzwe nibishobora kugaragara mugihe cyo guta umuringa harimo:

Gufata bidahagije:

Gufatanya nabi kurwego rwumuringa kuri substrate birashobora gutuma umuntu asiba cyangwa agashishwa. Isuku ikwiye neza, gukanika imashini, hamwe nubuvuzi butera imbere birashobora gufasha gukemura iki kibazo.

Ubunini bw'umuringa butaringaniye:

Umuringa utaringaniye urashobora gutera imiyoboro idahuye kandi bikabuza kohereza ibimenyetso. Kunonosora ibipimo byerekana, ukoresheje pulse cyangwa guhinduranya impanuka no kwemeza neza guhagarika umutima bishobora gufasha kugera kumubyimba umwe wumuringa.

Ubusa na Pinholes:

Ibyuho na pinholes murwego rwumuringa birashobora kwangiza amashanyarazi kandi byongera ibyago byo kwangirika. Kugenzura neza ibipimo byerekana no gukoresha inyongeramusaruro zikwiye birashobora kugabanya ibibaho byubusa na pinholes.

Ubuso bukabije:

Ubuso bukabije burashobora kugira ingaruka mbi kumikorere ya PCB, bikagira ingaruka kubishobora no gukomera kwamashanyarazi. Kugenzura neza ibipimo byo guta umuringa, kubanza kubanza kuvurwa hamwe na nyuma yubuvuzi bifasha kugera kubutaka burangiye.

Kugira ngo ibyo bibazo n’ibitagenda neza bigabanuke, hagomba gushyirwa mu bikorwa igenzura rikwiye, hagomba gukorwa ubugenzuzi n’ibizamini buri gihe, kandi hagomba gukurikizwa amahame n’inganda. Ibi byemeza ko umuringa uhoraho, wizewe kandi wujuje ubuziranenge kuri PCB. Byongeye kandi, gahunda ikomeje kunozwa, amahugurwa y'abakozi, hamwe nuburyo bwo gutanga ibitekerezo bifasha kumenya ahantu hagomba kunozwa no gukemura ibibazo bishobora kuba mbere yuko biba bikomeye.

Gushyira umuringa kuri substrate ya PCB nintambwe ikomeye mubikorwa byo gukora PCB. Amashanyarazi atagira amashanyarazi hamwe na electroplating nuburyo bwingenzi bukoreshwa, buriwese ufite ibyiza byawo kandi bigarukira. Iterambere ry'ikoranabuhanga rikomeje gutwara udushya mu kubika umuringa, bityo kuzamura imikorere ya PCB no kwizerwa.Ubwishingizi bufite ireme no kugenzura bigira uruhare runini mu kwemeza umusaruro wa PCB nziza. Nkuko ibyifuzo byibikoresho bya elegitoroniki bito, byihuse, kandi byizewe bikomeje kwiyongera, ni nako hakenerwa ubudashyikirwa no kuba indashyikirwa mu buhanga bwo kubika umuringa kuri substrate ya PCB. Icyitonderwa: Ijambo kubara ingingo ni amagambo agera ku 3.500, ariko nyamuneka menya ko ijambo nyirizina rishobora gutandukana gato mugihe cyo guhindura no gusuzuma.

Igihe cyo kohereza: Nzeri-13-2023

Inyuma