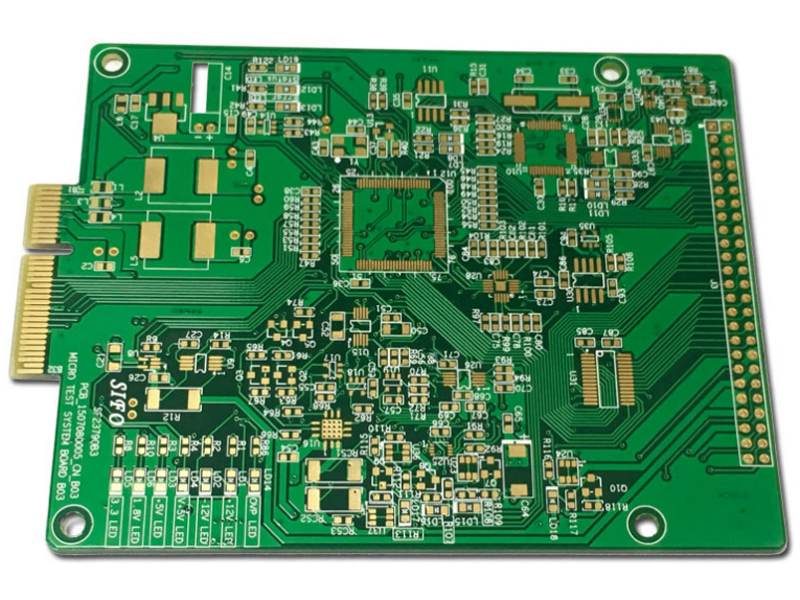

Niki PCBs Zisobanutse neza

Ikibaho cyiza cyane cyacapwe cyumuzunguruko, kizwi kandi nkibisobanuro bihanitse byacapwe byumuzunguruko,

ni ibikoresho bya elegitoronike bikoreshwa cyane mubisabwa bisaba imirongo nyayo kandi yuzuye.

Izi PCB zateguwe kandi zakozwe hitawe cyane kubisobanuro birambuye, byemeza urwego rwo hejuru rwukuri kandi rwizewe.

PCBs zisobanutse neza zikoreshwa cyane munganda nko mu kirere, ibikoresho byubuvuzi, itumanaho, n’imodoka. Zifite agaciro cyane mubisabwa bisaba uburinganire bwibimenyetso nyabyo, imikorere yumurongo mwinshi, kwihanganira gukomeye, hamwe no guhuza ikoranabuhanga.

Izi PCB zisanzwe zikoreshejwe hakoreshejwe uburyo nubuhanga bugezweho nko kugenzura imiyoboro ya impedance igenzurwa, ibice byiza byikibuga, micro vias, impumyi kandi zishyinguwe, hamwe nubucucike bukabije. Bashobora kandi gushiramo ibice byinshi, imirongo igoye hamwe nibikoresho byihariye kugirango byuzuze ibisabwa byihariye bigenewe.

Igikorwa cyo gukora PCBs zisobanutse neza zirimo ingamba zikomeye zo kugenzura ubuziranenge, harimo nogupima cyane no kugenzura, kugirango ibicuruzwa byanyuma byujuje ibisabwa. Ubu busobanuro nukuri bushoboza gukora neza kandi byizewe, cyane cyane muri sisitemu ya elegitoroniki igoye.

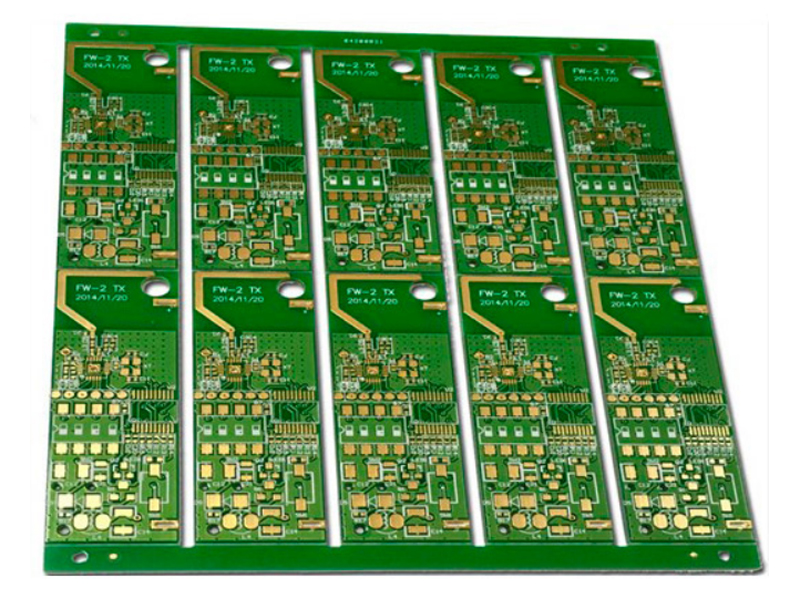

CAPEL PCBs Zisobanutse neza

PCBs zisobanutse neza zagenewe gutanga amashanyarazi yizewe kandi yuzuye. Banyura mubikorwa bitandukanye byinganda zumwuga kandi bakurikiza ibipimo ngenderwaho no kugerageza kugirango bahuze ibyifuzo byihariye bisabwa mubikorwa bitandukanye.

Ibikoresho byo mu rwego rwo hejuru

Ubusanzwe PCBs ikorwa hifashishijwe ibikoresho byujuje ubuziranenge, nka laminate yihariye yihuta cyangwa ceramika yateye imbere. Ibi bikoresho bifite imiterere yihariye ifasha kunoza imikorere ya PCB amashanyarazi nuburinganire bwikimenyetso.

Imiterere myinshi

Ubusanzwe PCBs zifite imiterere-yimiterere myinshi, ituma ibishushanyo mbonera byuzuzanya kandi byimbitse. Ubwubatsi butandukanye bufasha kunoza ibimenyetso byo kwigunga, kugabanya inzira no guhuza ingufu.

Umurongo mwiza n'umwanya

PCBs isobanutse neza ikenera umurongo mwiza cyane nubugari bwumwanya, mubisanzwe bipimirwa muri micron. Izi nzira zifunganye zituma ibimenyetso byerekana neza kandi bigabanya gutakaza ibimenyetso cyangwa kwivanga.

Kugenzurwa

Kugenzura Impedance ningirakamaro mugukomeza ibimenyetso mubisobanuro byihuse. PCB isobanutse neza igenzura impedance yumurongo wose kugirango ihuze inzitizi iranga isabwa nigishushanyo.

Ikoranabuhanga rigezweho

Ubusanzwe PCBs ikoresha tekinoroji igezweho yo gukora nka laser yo gucukura no gufata amashusho ataziguye. Gucukura Laser ituma bito, bisobanutse neza binyuze mubipimo, mugihe amashusho ataziguye atuma abiyandikisha bagurisha neza.

Kwipimisha no Kugenzura

Kugenzura ubuziranenge nibyingenzi kuri PCBs zisobanutse neza. Uburyo bukomeye bwo kwipimisha no kugenzura nko kugenzura optique (AOI) no kugenzura X-ray bikoreshwa kugirango hamenyekane inenge cyangwa ibibazo bishobora guterwa no kwemeza ko PCB yujuje ibyangombwa bisabwa.

Igishushanyo mbonera

PCBs isobanutse neza isaba ibitekerezo bya DFM byuzuye mugice cyo gushushanya kugirango tumenye neza ko ibishushanyo bishobora gukorwa neza kandi neza. Tekinike ya DFM ifasha guhindura igishushanyo mbonera cyibikorwa no kongera umusaruro muri rusange.

Ibice bito

PCBs zisobanutse neza akenshi zashizweho kugirango zemere ibice bito bito nkibikoresho byo hejuru byububiko bwa microelectromechanical sisitemu (MEMS). Gushyira neza no kugurisha neza ibyo bice bito bigira uruhare mubikorwa rusange bya PCB.